Fero Product LLC is a manufacturing, trade and services company, with an emphasis on wire production and trade.

Besides the production of coiled and filamentary wire rods, Fero Produkt LLC produces a great number of products: 70 different types of nails, hot dip galvanized wire, griffel, schulz, light steel mesh, rabitz mesh / glass mesh, galvanized steel spiked wires, panel fences and other types of nets.

Featured products

Raw material for the production of wire products is a hot-rolled wire from which a light-drawn wire is produced by the process of cold drawing, which is used for the production of wire products. Galvanized wire of various diameters is also used for production purposes.

Fero Produkt’s plastification of metal

Plastification of metals is an innovative way of “painting” metal surfaces. It is called “plastification” because the dyeing is done with the powder instead of classic paint. A plasticized surface is much more durable and of higher quality than surfaces painted with liquid paint. Colors are used from the RAL palette, so different shades can be obtained.

The basic steps of the plastification process consist of:

In the beginning, it is very important to thoroughly degrease and clean the surface. Our trained staff take this step very seriously because it is the basis for the high quality of all the next steps. It is done using water and chemicals in special conditions.

Subsequently, the metal is transferred to a dryer, where it is dried to 100% dryness and a powder plastic is applied to the surface thus prepared. The plasticised article must be electrified in order to seal the powder, which is of the opposite polarity.

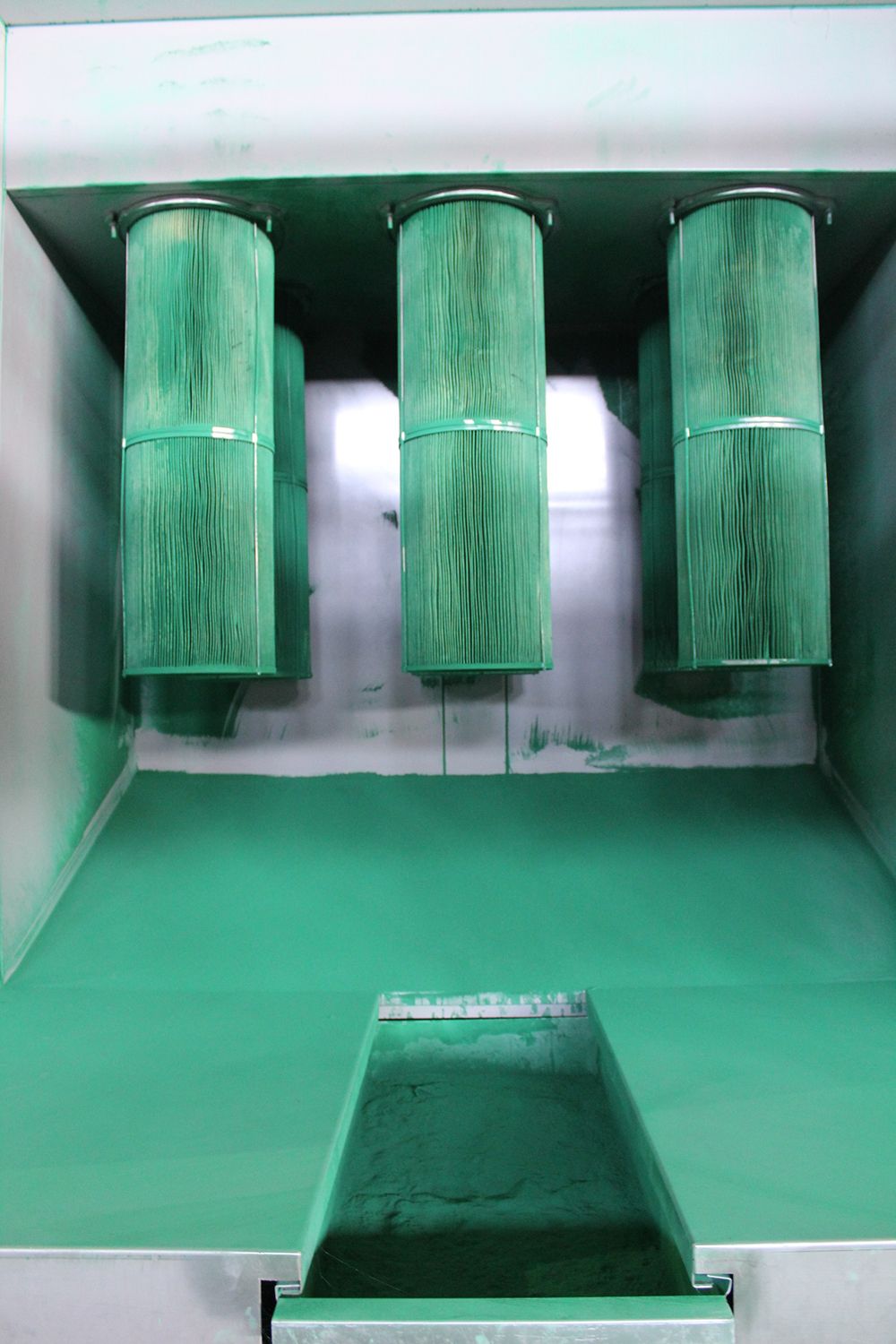

Electricity attracts powder on the parts where there isn’t any, and repels where too much is applied. The advantage is that in this way the powder is spread over the entire surface evenly, without duplicate layers and leaks. Application is carried out with electrostatic spray guns.

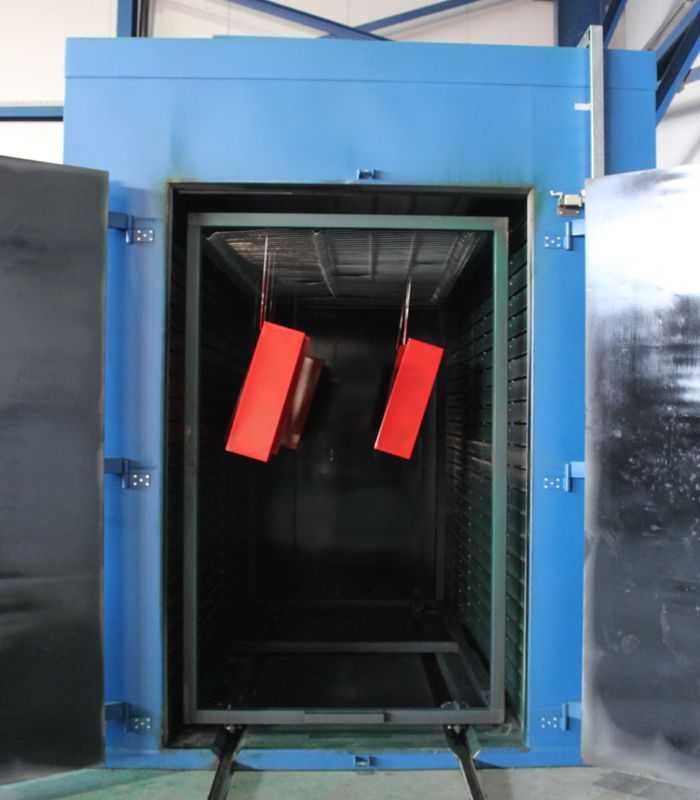

When the powder is applied, the polymerization process is followed by baking at 180 to 200° C for about 30 minutes where the powder melts and spills into an uniform layer of protective plastic.

Cooling soon follows, when the powder from the semi-liquid state returns to a permanent solid state in a strictly controlled clean environment.

Finally, the cooled item is carefully packed and palletized and as such is ready for safe transport to the customer.

About Fero Produktu

At the end of the 1990s, he bought the factory in today ‘s Novi Bečej, where the production of wire products started, and in 2016 the facilities of the former Milan Vidak factory in Futog.

Today, besides the production of coiled and filamentary wire rods, Fero Produkt LLC. Produces a great number of products: 70 different types of nails, hot dip galvanized wire, griffel, schulz, light steel mesh, rabitz mesh / glass mesh, galvanized steel spiked wires, panel fences and other types of nets.